Innovation to Purify Lube

It has been proved that the cleanliness of lubricating oil is very critical and vital to expensive motors and machineries. Dust particles are the major cause of wear but they are inevitably existing in all kinds of oil circulating systems, motors, engines, and hydraulic systems. Traditionally, a full flow filter is used to stop the large particles from flowing back in the lubricating oil system. However, it cannot handle small particles and needs to be replaced frequently. In brief, the traditional filter does not CLEAN the oil at all and it's very costly and inefficient.

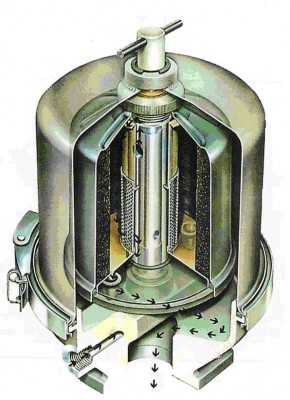

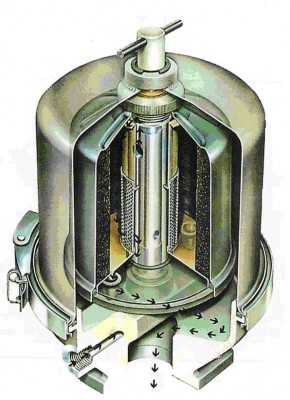

Now, we have a prefect solution for you. A patented centrifugal filter (China Patent# 200520026721.6; Taiwan Patent# 200520026721), UCF-II, has been developed that not only can it CLEAN oil but is capable of separating water from oil to ensure high purity level of lube oil. In addition, UCF-II is a self-driven high speed unit, where the rotator is only powered by oil pressure at the speed up to 4000-6000 rpm, providing a centrifugal force 2000 times greater than gravity. The centrifugal force creates a significant power to separate all kinds of dust and particles out of oil, even the smallest size down to

1μm. It does CLEAN the oil and literally prolongs the oil's and equipments' life.

Say Goodbye to Filter Replacement.

UCF-II never requires you to buy new replacement filters. The dust particles are collected in a tray. All you have to do is to take out the tray, wash it with kerosene and wash oil, put it back, and you are done. It's very simple and only costs you.....kerosene and wash oil.

Comparison of UCF-II and conventional full flow filter

|

UCF-II Centrifugal Filter |

Conventional Full Flow Filter |

| Large Particles |

Removed. Never jam the filter. ★ |

Stopped. Jam the filter. |

| Small Particles |

Removed. ★ |

Go through it and back to system. |

| Clean Oil |

Yes. ★ |

No. |

| Filter Replacement |

You don't have to buy any parts and accessories afterwards. ★ |

You have to buy and replace filters frequently until...you have UCF-II. |

| Oil Change |

Required but not frequent. ★ |

Frequent. Oil gets dirty easily because of accumulative small dust particles. |

| Machinery Life |

Longer. ★ |

Short. |

| Remove Water |

Yes. ★ |

No. |

U

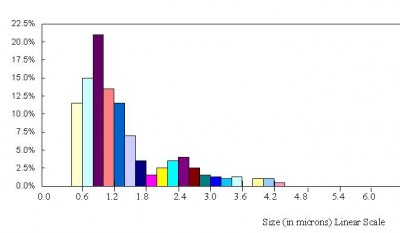

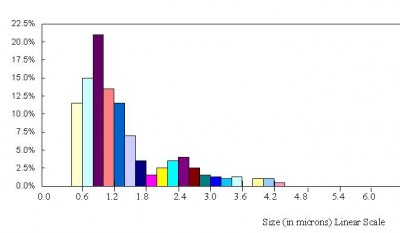

UCF-II can remove a wide size range of particles in lubricating oil. We analyze the dust particles collected from UCF-II's dust tray and find the particle size distribution as following.

As table shows, over 90% of the dust particles are in the size less than 2μm, which conventional full flow filters cannot handle at all. UCF-II removes those dust particles and really does a clean job.

Applications: To clean all types of lubricating oil

1. Steel: Hydraulic oil, gear oil, lubricating oil and cooling oil.

2. Ship: Lubricating oil.

3. Refinery: Hydraulic oil, gear oil, lubricating oil and cooling oil.

4. Metalworking: Cooling oil, compressor oil.

5. Power plant : Generator, lubricating oil, etc.

6. Paper: Hydraulic oil, circulating oil, gear oil.

7. Cement: Lubricating oil, gear oil.

8. Vehicle: Lubricating oil.

9. Plastic: Injection molding machinery

Benefits

1. Prolong the life of expensive engines and machineries.

2. Hold dust particles 5 times greater than conventional filter.

3. Replacement free. No need to replace any accessories. Only need to wash it with water.

4. Compact size. Doesn't occupy much space.

5. Remove all sized particles, even the very small ones that conventional filters cannot handle.

6. Prolong the life time of lubricating oil.

7. Low cost. Saves you lots of money.

8. Significantly decrease downtime of machineries. It cleans the oil when the machine is running.

UCF Filter Recommended Specification

| UCF Type |

UCF-1 |

UCF-5 |

UCF-10 |

| UCF Filter |

Weight (kg) |

3 |

18 |

25 |

| Dimension (φ*H, mm) |

|

203 * 344 |

|

| Minimum oil feed bose size (inch) |

0.5 |

0.75 |

1 |

| Minimum oil outlet pipe size (inch) |

1.5 |

2 |

3 |

| Filter oil capacity (liter) |

< 1,000 |

< 5,000 |

< 10,000 |

| Filter dirt capacity (liter) |

0.6 |

2.0 |

6.0 |

| Maximum oil temperature (℃) |

< 100 |

| Maximum oil viscosity (cSt) |

< 460 |

| Oil Pump |

Output pressure (kg/cm2) |

0-10 |

| Output flow rate (liter/hr) |

600 |

1,320 |

4,500 |

| Minimum hydraulic hose (inch) |

0.5 |

0.75 |

Inlet 1.25, Outlet 1 |

| Oil Pressure regulator (kg/cm2) |

0-10 |

| Motor |

Voltage (volt) |

220/380 |

| Horse Power (hp) |

0.5 |

1 |

3-5 |

※ UCF-1 and UCF-10 will be available in the end of 2007.

Outstanding Results from Our Clients

Outstanding Results from Our Clients

1.

China Steel Corporation

China Steel Corp. had been using 5μm conventional full flow filter on their equipments for many years. After switching to UCF-II and having it run for a while, they opened the UCF-II and still found lots of accumulated dust. In order to understand the distribution of particle size, they did mass spectrographic analysis by themselves and got a result as following. The majority of particle sizes between 0.4-1.5 μm, which cannot be removed by 5μm conventional full flow filter. It's a strong evidence that UCF-II can really clean the lubricating oil and prolong the life of equipments.

2.

Anshan Iron and Steel Group Corporation

After using UCF-II on the hydraulic oil system for 30 days, the NAS level is upgraded to level 3 from level 5.

3.

Shanghai Bao Shan Steel

Their hydraulic oil systems required them to replace 4-6 full flow filters (USD700-800) every week and consumed 20 drums of lubricating oil every month. After installing UCF-II and having it run for 360 hours, the NAS is substantially improved from level 9 to level 5. They don't need to change the oil so frequently and never need to buy the replacement filter.

4.

China National Petroleum Corporation -- Ta-Shi-Nan Oil Field

They use Mobile 701 lubricating oil in the compressor machines DPC-800. Before using UCF-II, the oil contained 0.0297% of impurities and 0.017% of water after 8 months of use. The oil looked muddy and dark brown. After using UCF-II, they found that the oil contains 0% of impurities and water. The oil is light yellow and clear after 8 months of use. We suggest them to replace the oil every 8,000 hours but now it has been running more than 15,000 hours without shutdown.

5.

Tonghua Iron & Steel Group Co., Ltd

They add a UCF-II on the hydraulic oil system which still has conventional full flow filter. They used to replace the full flow filter every 15-20 days. With UCF-II, now they only need to replace the conventional full flow filter every 180 days.

Wanna try it?

We highly recommend you to order one and you will believe it as you see it. With a

ONE-TIME charge, you will get the excellent oil quality much better than you could ever imagine. Wash UCF-II with water as needed. No hassle on filter replacement anymore.

Save money on replacement filter.

Save money on oil change.

Save money on machinery maintenance.

Make money on less downtime.

Make money on better performance.

UCF-II can remove a wide size range of particles in lubricating oil. We analyze the dust particles collected from UCF-II's dust tray and find the particle size distribution as following.

As table shows, over 90% of the dust particles are in the size less than 2μm, which conventional full flow filters cannot handle at all. UCF-II removes those dust particles and really does a clean job.

Applications: To clean all types of lubricating oil

1. Steel: Hydraulic oil, gear oil, lubricating oil and cooling oil.

2. Ship: Lubricating oil.

3. Refinery: Hydraulic oil, gear oil, lubricating oil and cooling oil.

4. Metalworking: Cooling oil, compressor oil.

5. Power plant : Generator, lubricating oil, etc.

6. Paper: Hydraulic oil, circulating oil, gear oil.

7. Cement: Lubricating oil, gear oil.

8. Vehicle: Lubricating oil.

9. Plastic: Injection molding machinery

Benefits

1. Prolong the life of expensive engines and machineries.

2. Hold dust particles 5 times greater than conventional filter.

3. Replacement free. No need to replace any accessories. Only need to wash it with water.

4. Compact size. Doesn't occupy much space.

5. Remove all sized particles, even the very small ones that conventional filters cannot handle.

6. Prolong the life time of lubricating oil.

7. Low cost. Saves you lots of money.

8. Significantly decrease downtime of machineries. It cleans the oil when the machine is running.

UCF Filter Recommended Specification

UCF-II can remove a wide size range of particles in lubricating oil. We analyze the dust particles collected from UCF-II's dust tray and find the particle size distribution as following.

As table shows, over 90% of the dust particles are in the size less than 2μm, which conventional full flow filters cannot handle at all. UCF-II removes those dust particles and really does a clean job.

Applications: To clean all types of lubricating oil

1. Steel: Hydraulic oil, gear oil, lubricating oil and cooling oil.

2. Ship: Lubricating oil.

3. Refinery: Hydraulic oil, gear oil, lubricating oil and cooling oil.

4. Metalworking: Cooling oil, compressor oil.

5. Power plant : Generator, lubricating oil, etc.

6. Paper: Hydraulic oil, circulating oil, gear oil.

7. Cement: Lubricating oil, gear oil.

8. Vehicle: Lubricating oil.

9. Plastic: Injection molding machinery

Benefits

1. Prolong the life of expensive engines and machineries.

2. Hold dust particles 5 times greater than conventional filter.

3. Replacement free. No need to replace any accessories. Only need to wash it with water.

4. Compact size. Doesn't occupy much space.

5. Remove all sized particles, even the very small ones that conventional filters cannot handle.

6. Prolong the life time of lubricating oil.

7. Low cost. Saves you lots of money.

8. Significantly decrease downtime of machineries. It cleans the oil when the machine is running.

UCF Filter Recommended Specification

Outstanding Results from Our Clients

1. China Steel Corporation

China Steel Corp. had been using 5μm conventional full flow filter on their equipments for many years. After switching to UCF-II and having it run for a while, they opened the UCF-II and still found lots of accumulated dust. In order to understand the distribution of particle size, they did mass spectrographic analysis by themselves and got a result as following. The majority of particle sizes between 0.4-1.5 μm, which cannot be removed by 5μm conventional full flow filter. It's a strong evidence that UCF-II can really clean the lubricating oil and prolong the life of equipments.

Outstanding Results from Our Clients

1. China Steel Corporation

China Steel Corp. had been using 5μm conventional full flow filter on their equipments for many years. After switching to UCF-II and having it run for a while, they opened the UCF-II and still found lots of accumulated dust. In order to understand the distribution of particle size, they did mass spectrographic analysis by themselves and got a result as following. The majority of particle sizes between 0.4-1.5 μm, which cannot be removed by 5μm conventional full flow filter. It's a strong evidence that UCF-II can really clean the lubricating oil and prolong the life of equipments.

2. Anshan Iron and Steel Group Corporation

After using UCF-II on the hydraulic oil system for 30 days, the NAS level is upgraded to level 3 from level 5.

3. Shanghai Bao Shan Steel

Their hydraulic oil systems required them to replace 4-6 full flow filters (USD700-800) every week and consumed 20 drums of lubricating oil every month. After installing UCF-II and having it run for 360 hours, the NAS is substantially improved from level 9 to level 5. They don't need to change the oil so frequently and never need to buy the replacement filter.

4. China National Petroleum Corporation -- Ta-Shi-Nan Oil Field

They use Mobile 701 lubricating oil in the compressor machines DPC-800. Before using UCF-II, the oil contained 0.0297% of impurities and 0.017% of water after 8 months of use. The oil looked muddy and dark brown. After using UCF-II, they found that the oil contains 0% of impurities and water. The oil is light yellow and clear after 8 months of use. We suggest them to replace the oil every 8,000 hours but now it has been running more than 15,000 hours without shutdown.

5. Tonghua Iron & Steel Group Co., Ltd

They add a UCF-II on the hydraulic oil system which still has conventional full flow filter. They used to replace the full flow filter every 15-20 days. With UCF-II, now they only need to replace the conventional full flow filter every 180 days.

Wanna try it?

We highly recommend you to order one and you will believe it as you see it. With a ONE-TIME charge, you will get the excellent oil quality much better than you could ever imagine. Wash UCF-II with water as needed. No hassle on filter replacement anymore.

Save money on replacement filter.

Save money on oil change.

Save money on machinery maintenance.

Make money on less downtime.

Make money on better performance.

2. Anshan Iron and Steel Group Corporation

After using UCF-II on the hydraulic oil system for 30 days, the NAS level is upgraded to level 3 from level 5.

3. Shanghai Bao Shan Steel

Their hydraulic oil systems required them to replace 4-6 full flow filters (USD700-800) every week and consumed 20 drums of lubricating oil every month. After installing UCF-II and having it run for 360 hours, the NAS is substantially improved from level 9 to level 5. They don't need to change the oil so frequently and never need to buy the replacement filter.

4. China National Petroleum Corporation -- Ta-Shi-Nan Oil Field

They use Mobile 701 lubricating oil in the compressor machines DPC-800. Before using UCF-II, the oil contained 0.0297% of impurities and 0.017% of water after 8 months of use. The oil looked muddy and dark brown. After using UCF-II, they found that the oil contains 0% of impurities and water. The oil is light yellow and clear after 8 months of use. We suggest them to replace the oil every 8,000 hours but now it has been running more than 15,000 hours without shutdown.

5. Tonghua Iron & Steel Group Co., Ltd

They add a UCF-II on the hydraulic oil system which still has conventional full flow filter. They used to replace the full flow filter every 15-20 days. With UCF-II, now they only need to replace the conventional full flow filter every 180 days.

Wanna try it?

We highly recommend you to order one and you will believe it as you see it. With a ONE-TIME charge, you will get the excellent oil quality much better than you could ever imagine. Wash UCF-II with water as needed. No hassle on filter replacement anymore.

Save money on replacement filter.

Save money on oil change.

Save money on machinery maintenance.

Make money on less downtime.

Make money on better performance.

English

English  Vietnamese

Vietnamese  繁體中文

繁體中文